Component analysing laboratory

If we would like to analyze a turbocharger, we have variable possibilities, for example a test-bench, which has lot of benefits in the field of materiality and efficiency. Using this kind of analysis, we can get a better adjustable system than we use an engine test-bench, that’s why our measurements will be more targeted and reproducible.

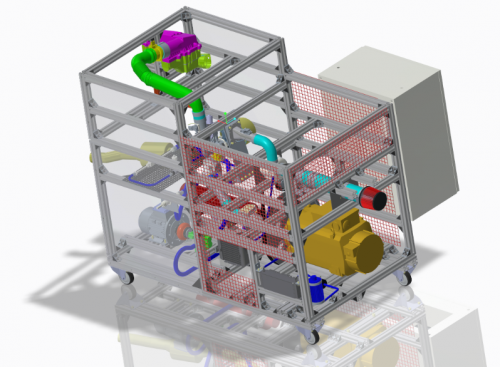

So the goal is to develop a cold powered test-bench, which is suitable for model the most requirements of a turbocharger.

It’s an important specific of the test-bench, that while a hot powered test-bench has a burner (which models the energy of the exhaust gas), at the cold powered test-bench the turbocharger is driven by an electric motor and a radial compressor. This machines product the needed air massflow and the needed pressure.

The main goal of this project is to model the lifetime of the parts (considering in the different working points) and the wears caused by the different types of tribological requirements.

Operating with a cold powered test-bench has further advantages, for example making school experiments, thermodynamic and acoustical measurements and to determine the optimal working points.

Specification:

- Air preparation: ROTREX C30 radial compressor

- Propulsion: electric engine 29 kW

- Oil massflow: 0,2-10 l/min

- Oil pressure: 0,1-15 bar

Testing options:

- Cold start

- Polluted oil

- Low viscosity oil

- Unsatisfactory lubricant processes

- Foreign particulars: sand, dust in the system

- The heat reqirement of the tribological system

- High speed of revolition

Current projects: