In the development phase of the internal combustion engines various tribometers are used for the comparison of several material compositions. With these methods, a huge amount of time and cost can be reduced, because the variations can be analyzed in a short time. In the mechanical word several standards exist, not only for the whole internal combustion engines, but also for the part of it.

This examination machines are able to measure tiny friction differences between the variations and it is not necessary to burn fuel to make the measurements and also the number of the test parameters are also minimal.

The equipment and software of the labor

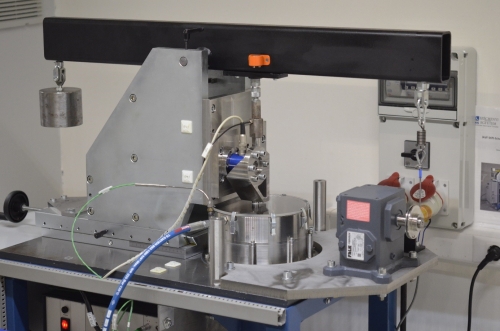

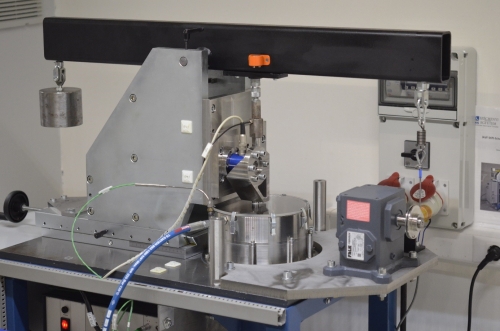

IAVF pin-on-disc tribometer

|

|

- Purchase year: 2012

- Movement pattern: rotate

- Maximum revolution: 1500 prm

- Maximum movement radius: 15 mm

- Maximum load: 500N/2000N, depend on the force measurement sensor

- Lubrication:

- oil pump, with the oil temperature up to 90°C

- micropump, on laboratory temperature

- Usage of this machine:

- comparison of lubricants

- comparison of surface coatings

- comparison of surface working processes

- online wear measurement with radionuclide technology

|

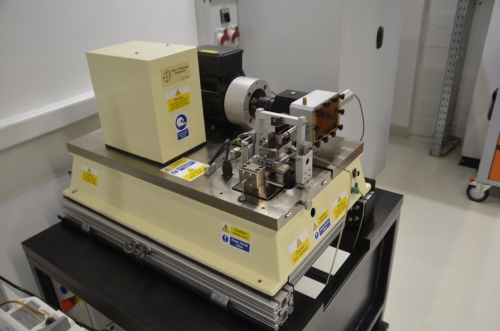

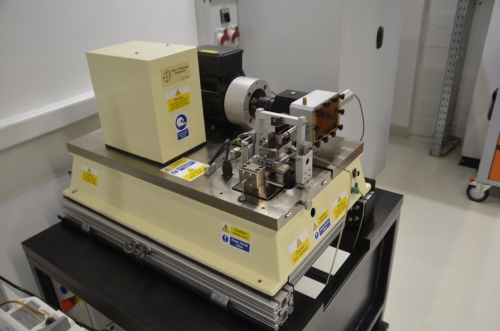

Plint TE-77 High Frequency Friction Machine

|

|

- Purchase year: 2012

- Movement pattern: oscillation

- Maximum stroke: 25 mm

- Maximum frequency: 50 Hz

- Maximum load: 1000N

- Temperature: heating the test bodies up to 650°C

- Lubrication:

- Usage of this machine

- characterization of cylinder liner coatings

- characterization of piston rings

- investigation of timing chain parts

- investigation of several manifold materials

- comparison of several lubricants

- tribological investigation of several systems with oscillation movement pattern

|

Optimol SRV5 Tribometer

|

|

- Purchase year: 2016

- Movement pattern: oscillation, revolution or combined

- Maximum stroke: 5 mm

- Maximum frequency: 500 Hz

- Maximum movement radius (revolution movement): 45 mm

- Maximum revolution (revolution movement) 2000 rpm

- Temperatures: heating the test bodies up to 350°C

- Lubrication:

- oil bath

- micro pump up to 800 ml/h throughout and up to 150°C temperature of the oil

- Usage of this machine:

- characterization of cylinder liner coatings

- characterization of piston rings

- investigation of timing chain parts

- investigation of several manifold materials

- comparison of several lubricants

- standard investigation methods:

- ISO 7148 – plain bearings testing

- ISO 12156 – diesel fuel testing

- ISO 19291 – lubricants testing

|

Álmos Dávid Tóth

Assistant lecturer

More information